3-Way MB Series Miniature Direct Acting Valves

Key Features

- Designed for small air cylinders and clamps

- Suited for applications requiring low air flow

- Manifolds can be bolted together to provide the desired banking combination

- Direct Acting, Multi Purpose Valves

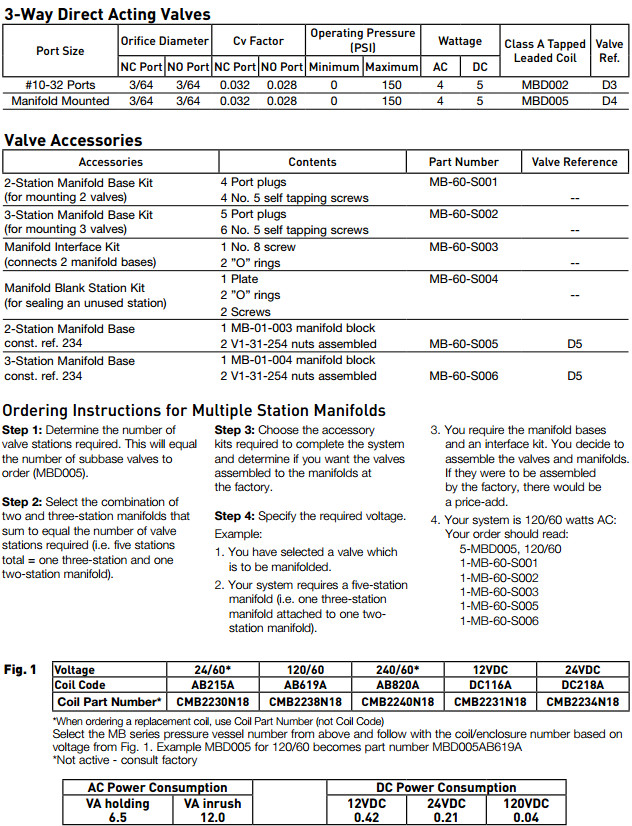

- Up to 150psi, consuming 4 watts per coil on AC operation, 5 watts per coil on DC

- Can be customized as 2-way NO or NC, 3-way NO or NC or Directional Control

Sizes:

- 10-32

- 1/8 NPT

- Manifold Mount

MB Series valves are designed for the actuation of small air cylinders and clamps, and are suited for applications requiring low air flow. For manifolding, 2 or 3 station bases are offered. Manifolds can be bolted together to provide the desired banking combination. The valves are direct acting, multipurpose valves with all ports in the body. The valve body is molded from plastic, while the internal parts are nylon, polyester and stainless steel. The valves will operate at up to 150 PSI, consuming only 4 watts per coil on AC operation, 5 watts per coil on DC. Functional design flexibility is assured given the wide variety of available valve configurations. The listed accessories enable the user to customize MB Series valves as 2-way normally open or normally closed by plugging one port; 3-way normally open, normally closed or directional control.

Standard Materials of Construction

- Body—plastic

- Seals—NBR

- Sleeve—stainless steel (305)

- Plunger—stainless steel (430FR)

- Stop—stainless steel (430FR)

- Spring—stainless (17-7PH)

- Shading ring—copper (AC valves only)

- Manifold base—zinc

Operating Speed

- Up to 1000 cycles per minute

Coil Classification

- Class A Taped, leaded coil standard

Response Time (approximate):

- AC: 3-12 ms to open

- 5-16 ms to close

- DC: 8-14 ms to open

- 5-15 ms to close

Electrical Characteristics:

Voltages

- AC—24/60, 120/60, 240/60

- DC—12, 24 &120

Power Consumption

- 4 watts AC per coil

- 5 watts DC per coil

Maximum allowable internal seat leakage is 3 SCCM @125 psi.

No allowable external leakage.

Compatible Fluids

- Lubricated air, non-lubricated air, and inert gases compatible with materials of construction.