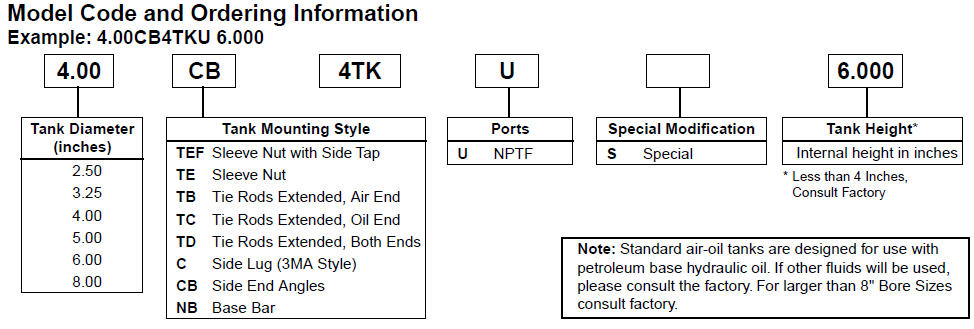

Parker Pneumatic

4TK Series Air-Oil Tanks

THIS PRODUCT IS RETIRED. CONTACT MFCP/COMOSO FOR SUGGESTED REPLACEMENTS

Key Features

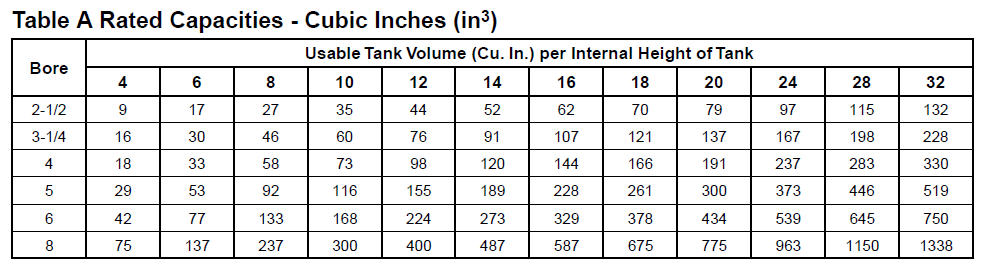

- Standard Bore Sizes 2-1/2" - 8"

- Operating Pressure 250 PSI Maximum

- Operating Temperature 165°F Maximum

- Lightweight Aluminum / Fiberglass Design

- Larger Bore Sizes Available Upon Request

Air-Oil Tanks – For Smoother Hydraulic Flow

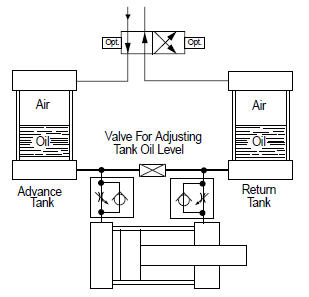

Air-Oil tanks provide a means to convert shop air pressure into hydraulic pressure. Compressed air is applied directly to the oil in the air-oil tank to convert it into hydraulic pressure. The hydraulic pressure is at a 1-to-1 ratio, i.e. 80 psi air produces 80 psi hydraulic pressure.

All Parker Air-Oil tanks have a fiberglass tube which shows the proper oil level. They also contain two fluid flow baffles. The top baffle disperses the incoming air over the surface of the oil in such a way to avoid agitation and aeration. The bottom baffle insures a smooth flow pattern that minimizes oil turbulence and eliminates swirling, funneling or splashing which in turn could cause oil aeration or the oil to be blown from the tank into the exhaust air.

Air-Oil tanks are used to smooth out the cylinder piston rod travel and to prevent chatter. They are mainly used in slow speed circuits. Since each tank is designed for a specific port size, increasing the port size in a tank to lower the fluid velocity is not recommended. A tank with a larger port size should be selected.

Fluid velocity in or out of the tank through standard ports should be less than 6 feet per second to prevent aeration of the oil. To limit the fluid velocity, flow controls should be applied to the air side of the tank to restrict the exhaust. Metered-in flow controls on the air side may aid in the reduction of aeration. Additional flow controls on the oil side may aid in controlling the actuator motion.