Parker Hydraulic Group

Dual Axis Knuckle

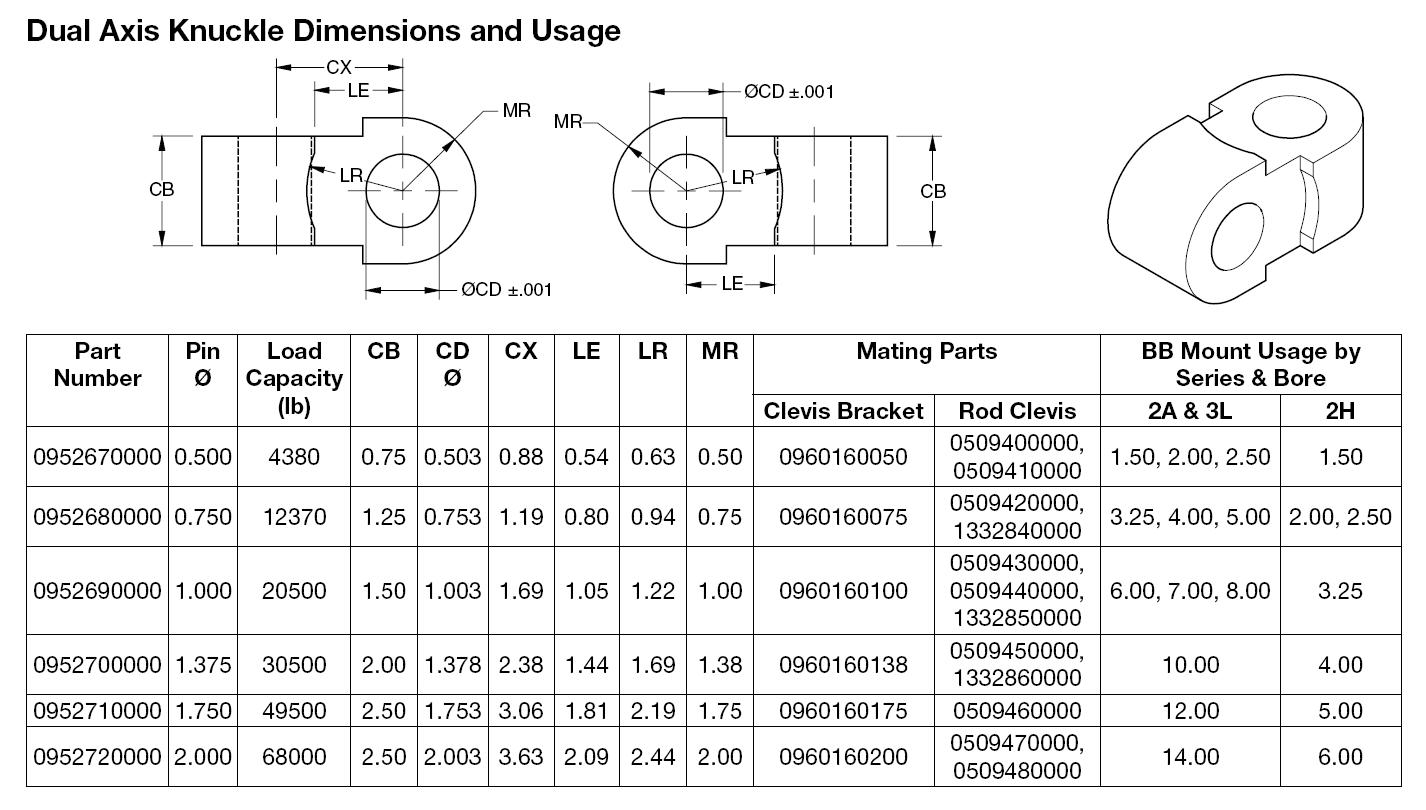

Dual Axis Knuckle

Key Features

- Increased angular movement range compared to spherical bearing mount.

- Significantly higher dynamic load rating than spherical bearing mount.

- Reduced bearing loads and wear that results from misalignment.

- Allows faster assembly of pivoting cylinders to the machine.

Using a Dual Axis Knuckle permits increased angular movement from the cylinder center line. Clevis or Eye mounted cylinders often require movement beyond the plane that two pivot pins allow. Spherical bearing mounts permit angular movement up to 4.5° within the pivoting plane. A Dual Axis Knuckle, with two pin holes 90° apart, installed at the cap and rod end of a mounting style BB cylinder adds two pivot points, thereby providing up to 30° movement in another plane at each end.

Catalogs

551.6 kB