Parker Hydraulic Group

V20EH Series Open-Center Directional Control Valve

V20EH Series Open-Center Directional Control Valve

Key Features

- A global solenoid (pwm) that can be used for proportional or on/off control. The coils have a molded on Amp Jr. or Deutsch connector.

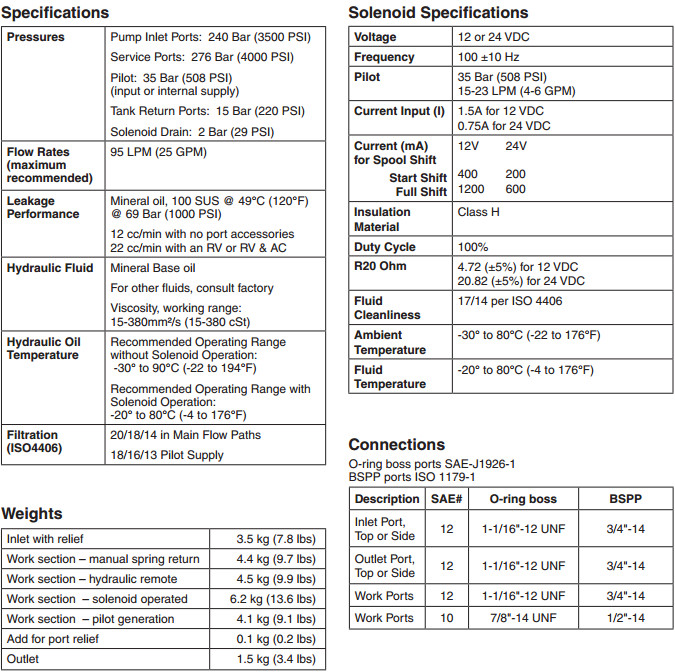

- Work sections rated to 240 Bar (3500 PSI): 4-way, 3-position; and 3-way, 3-position.

- A pilot generating/regulating section that is referred to as a utility section. The purpose of this section is to generate and regulate pilot pressure in an opencenter circuit. This section is to be placed adjacent to the outlet cover.

Benefits

- The pressure required to move the spools is generated and regulated internal to the V20 valve. This eliminates the need for any in-line devices and the associated plumbing which saves installation cost.

- Minimal impact on open-center pressure drops when the main spools are in neutral. This is because pressure generation is “triggered” to on, only when a spool is selected. The benefit is less heat generation and reduced fuel consumption.

- Minimal impact on loop pressure drops: P-A/B and A/B-T which maximizes horsepower utilization.

- There is an option to have the mechanical buildup for full on-time operation, useful in many applications where the PTO is engaged only when work is to be done.

- A dedicated solenoid drain to the reservoir optimizes solenoid performance. This translates into consistent metering and machine controllability.

- An extended bonnet for screw-adjustable work port relief valves in an option available for those applicatons requiring this type of adjustable pressure control (consult factory).

- Handle with manual override.

Catalogs