VP120 Series Load-Sense Directional Control Valve

Key Features

- Excellent machine controllability - Delivers predictable metering

- Improved system efficiency - optimized horsepower utilization and heat management. Fuel savings up to 30%

- Enhanced machine productivity - the VP120 incorporates flow-sharing technology

- Enhanced Speed Control

- Reduced Heat Generation - VP120 allows for selected functions to operate at a pressure less than the setting of the load-sense relief-valve, while only passing a few liters of oil to tank

- Flexible Design

- Ease of Service - load-sense check and the compensator are located on the top of the work section, making them accessible for trouble-shooting without having to disassemble the valve bank.

The VP120 can be configured either as pressure compensated load-sense (PCLS) or as load-sense (LS). Both have the flexibility of sectional construction. The PCLS work section has its own compensator, so that speed control of multiple functions is achieved, regardless of changes in pressure or engine rpm’s. The key technology integrated into the VP120 is flow-sharing. In pump over-demand conditions, flowsharing benefits machine productivity by maintaining the speed relationship of the selected functions, but at a reduced speed. Thus, the operator can maintain the rhythm of the machine.

A new technology available in the VP120 is pressure-limiting. This feature allows for selected functions to operate at pressures lower than load sense relief-valve setting. The advantage of using pressure limiters to accomplish this vs. port relief valves is that less flow is lost – which means less heat generation.

Another new technology developed for the VP120 is margin control, which can be used to selectively boost or reduce the flow out of a work-section.

The combination inlet/outlet can be installed on both ends of the valve, facilitating the routing of pump flow to both ends of the valve.

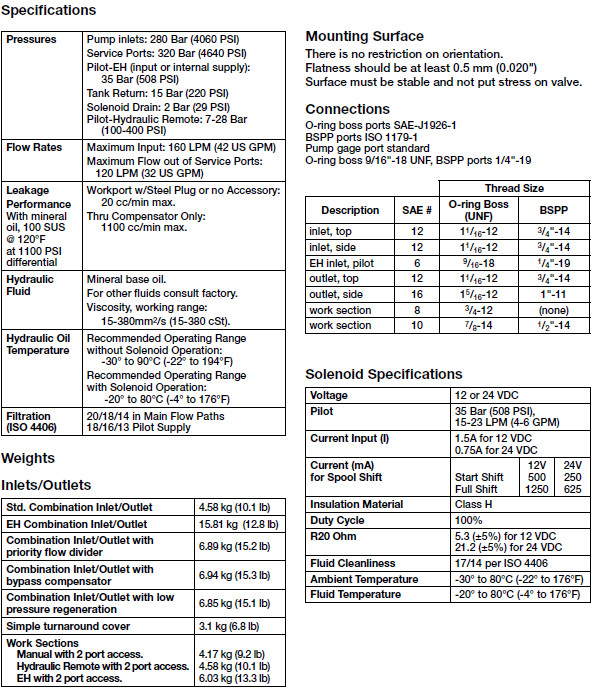

The valve can be operated manually, hydraulic remote and with solenoids. The same solenoid is used for on/off and proportional control. A bypass compensator is available for use with fixed displacement pumps. Also, priority flow control is an option for steering requirements. In addition, low pressure regeneration is an option designed to overcome the damaging affects of cavitation – namely premature component wear and spongy operation.

The VP120 uses the same port accessories, loadsense relief valve and pressure-reducing valve that are used in our other valves. The standard spool types are 3-way, 4-way and 4-position float. A full range of flow limited spools are available.

Applications

- Wheel loaders and bulldozers

- Cranes and material handling equipment

- Aerial work platforms, digger derricks and drill rigs