Greer

BA Series Bladder Accumulators

BA Series Bladder Accumulators

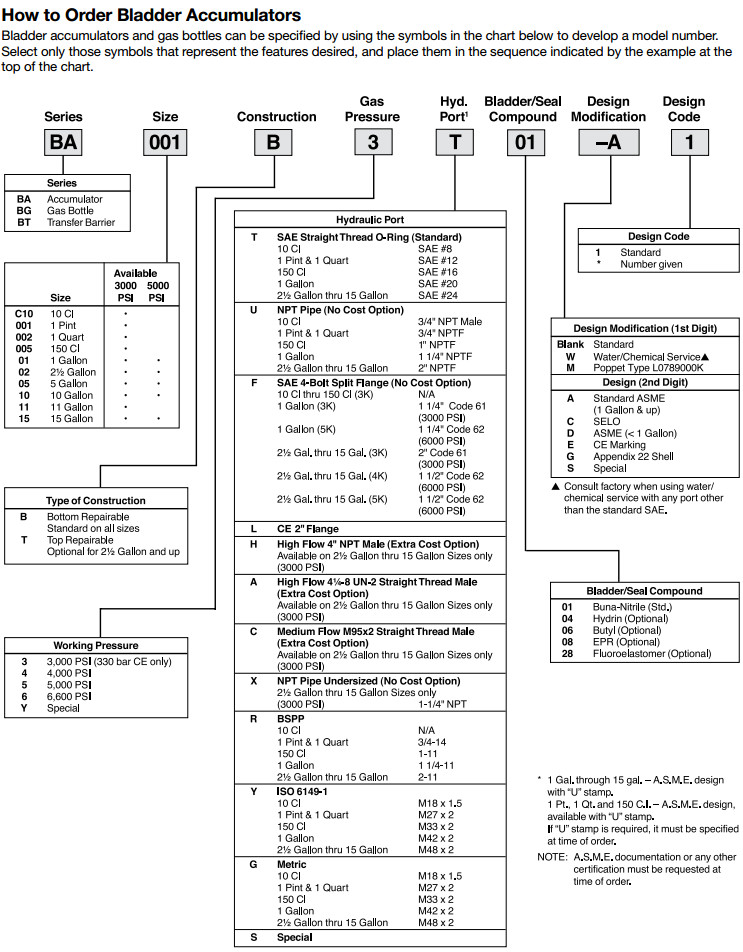

Available in these versions:

- 3000 & 5000 PSI Bottom Repairable

- 3000 & 5000 PSI Top Repairable

- 3000 PSI Medium Flow

- 3000 PSI High Flow

- 3000 PSI Transfer Barrier

- 3000 & 5000 PSI Gas Bottles

- A Wide Array of Options and Accessories

- Operating Pressures to 6600 PSI

- Ten Different Capacities from 10 cu in to 15 gallons

- Nine Different Configurations

- Highest Quality In-House Manufactured Bladders

- ASME Certification Standard, 1 Gallon & Up

- Water/Chemical Service Available, with Stainless Steel Ports

- Five Bladder Compounds to Suit a Variety of Fluids & Temperatures

- CE Marking Available

Bladder accumulators provide a means of regulating the performance of a hydraulic system. They are suitable for storing energy under pressure, absorbing hydraulic shocks, and dampening pump pulsation and flow fluctuations. Bladder accumulators provide excellent gas and fluid separation ensuring dependable performance, maximum efficiency, and long service life.

Materials

- Shell – high strength alloy steel (SA372, all sizes comply with ASME material specifications, 1 gal. & larger supplied with ASME Certification as standard)

- Ports – all oil service ports, high strength alloy steel

- Poppet & Spring – 304 stainless steel

- water & chemical service:

- 3000 psi, 304 stainless steel

- 5000 psi, 17-4 PH stainless steel

- 3000 psi, 304 stainless steel

- water & chemical service:

- Gas Valve Cartridge – steel

- Gas Valve Protector – steel

- Gas Valve Stem – steel

- Bladders – various polymers, see Standard and Optional Bladders.

Pressure Ratings

- 3000 and 5000 psi bladder accumulators are rated at minimum 4 to 1 design factors as standard.

- 4000 and 6600 psi (ASME Appendix 22) bladder accumulators are available as an option at minimum 3 to 1 design factors.

- For pressures over 6600 psi, consult the factory.

(max. working pressure/precharge pressure): 4 to 1.

Catalogs

1.3 MB