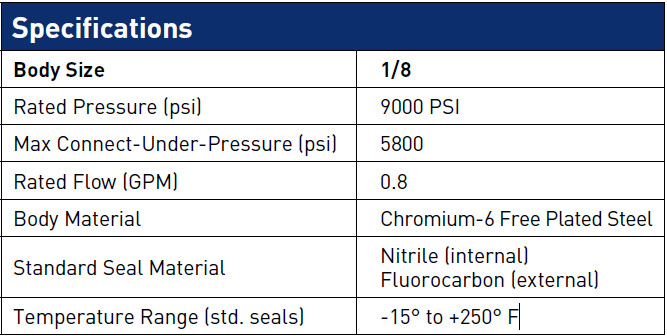

EMA3 Series Test Port Couplings

Key Features

- Knurled sleeve allows simple twist-to-connect operation without the use of tools

- Rugged design allows connect-under-pressure operation up to 5800 psi

- Maximum rated working pressure of 9000 psi exceeds the requirements of most applications

- Integral threaded dust cap protects the test point from damage and contamination

- EMA fittings are machined from solid barstock and protected with Chromium-6 Free plating.

- Stainless steel springs for corrosion resistance

- Elastomeric interface and valve seals provide leak free operation

- Compact design and optional high pressure hose assemblies provide flexibility for tight space requirements

EMA couplings provide easy diagnostic connections for Parker SensoControl® equipment or mechanical gages. EMA test points are typically permanently plumbed into a fluid system at locations where pressure measurements are required for maintenance or testing. Integral pressure cap protects the test point from damage and prevents contam-ination of the fluid system. Proven twist-to-connect design allows the test points to be connected even when the system is in operation and the test points are pressurized. EMA’s compact design and optional high pressure hose assemblies allow extra flexibility for the location of system test points.

Although designed primarily for diagnostic applications, EMA fittings and hose assemblies are idea for a wide range of applications that require compact high pressure connections and limited flow rates.