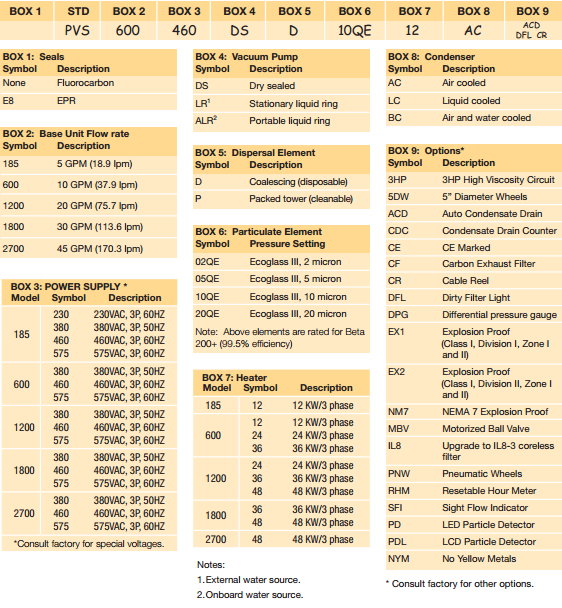

PVS Series Portable Purification Systems

Key Features

- Variable flow circuit

- Moisture sensor

- Automatic operation

- 316 Stainless steel used for primary wetted surfaces

- Ecoglass particulate element

- Clear plexiglass covers on the condensate tank and vacuum chamber

- Desiccant breather

- Reverse phase switch

- Condensate holding tank with optional auto drain

- Programmable thermostat

- Forklift guides and lifting eyes

- Coalescing or packed tower oil dispersal elements

Applications

- Hydraulic Systems

- Lubrication Systems

- Turbine Oil

- Transformer Oil

- New Oil (Oil Storage)

- Seal Oil

- Explosion Proof Environments

Contaminated oil is drawn into the Parker Portable Purification System (PVS) by a vacuum of 25 In/Hg. The oil passes through the in-line low watt density heater where the oil is heated to an optimum temperature of 150° F (66°C).

The oil then enters the distillation column where it is exposed to the vacuum through the use of special dispersal elements. This increases the exposed surface area of the oil and converts the water to vapor form, which is then drawn through the condenser by the vacuum pump.

The water-free oil falls to the bottom of the column and is removed by a heavy duty lube oil pump. This pump forces the dry oil through a final particulate removal filter. Clean oil passes out of the unit, back to the reservoir — and into the system.