Heated Viscometer

Key Features

- Monitoring viscosity gives an early warning for potential fluid issues.

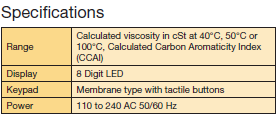

- Highly accurate results with two readings are available at 40°C, 50°C or 100°C.

- Test an even greater range of oils, by changing the viscosity index or density.

- Estimate the combustion performance (CCAI) of fuel oil.

- Heavy duty, robust equipment - ideal for long term use with fast and accurate results.

The Parker Heated Viscometer provides a condition monitoring tool that enables you to make informed operational and maintenance decisions about your critical plant and equipment. Fuel and lubricating oils form a major cost element in the operation of almost all industrial machinery and engines; the quality must be closely monitored to protect the investment. The ability to test onsite, at the point of use, enables engineers and facilities managers to conduct oil analysis quickly and easily. Detecting out-of-spec fuels or lubricants can identify potential problems before equipment damage occurs.

Viscosity is regarded as an oil’s most important characteristic. It is the viscosity that gives the oil’s resistance to fl ow and the strength of the oil film between surfaces. Viscosity can increase or decrease as a result of problems such as contamination, fuel dilution, and shear thinning. Measurement of viscosity is extremely important for hydraulic oils, diesel engine oils, gear, and fuel oils.

The heated viscometer measures a specific temperature point and is designed to ‘tilt’ from side to side in both directions, allowing the internal rolling ball to fall under gravity, enabling the viscosity of the oil to be calculated automatically.