Non-Reversing and Reversing NEMA Contactors

Key Features

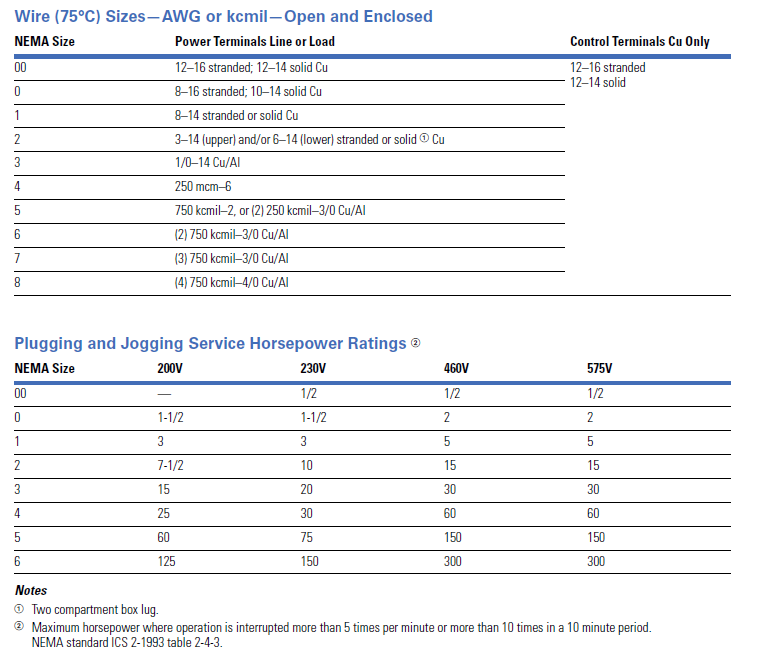

- Designed specifically for use in applications requiring NEMA ratings. Contactors meet or exceed NEMA standards ICS 2-1993

- Long life twin break, silver cadmium oxide contacts—provide excellent conductivity and superior resistance to welding and arc erosion

- Designed to 3,000,000 electrical operations at maximum hp ratings up through 25 hp at 600V

- Steel mounting plate standard on all open type contactors

Non-Reversing

Holding circuit contact(s) supplied as standard:

- Sizes 00–3 have NO auxiliary contact block mounted on right hand side (on Size 00, contact occupies 4th power pole position—no increase in width)

- Sizes 4–5 have a NO contact block mounted on left side

- Sizes 6–7 have a 2NO/2NC contact block on top left

- Size 8 has a NO/NC contact block on top left back and a NO contact block on top right back

Reversing

- One NO-NC side mounted interlock supplied as standard on each contactor for Sizes 00–8

Non-Reversing

Contactors are most commonly used to switch motor loads in applications where running overcurrent protection is either not required or is provided separately. Contactors consist of a magnetically actuated switch which can be remotely operated by a pushbutton station or pilot device such as a proximity switch, limit switch, float switch, auxiliary contacts, and so on.

Reversing

Reversing contactors are used primarily for reversing single- or three-phase motors in applications where running overcurrent protection is either not required or is provided separately. They consist of two contactors mechanically and electrically interlocked to prevent line shorts and energization of both contactors simultaneously.