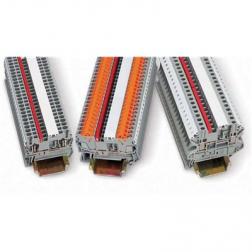

XB Series IEC Terminal Blocks Overview

Key Features

- Global acceptance

- Flexible plug-in bridge system

- Large surface area for marking

- Standardized testing system

Termination Choices

- Screw Connection

- Spring Cage

- Pluggable Spring Cage

- IDC - Insulation Displacement

The XB Series from Eaton offers a complete terminal block system with a universal range of accessories. Marking, bridging and testing accessories are standardized across the different termination technologies— reducing inventory and logistics costs. The modular terminal block design allows for use of the different terminal block types together or individually, providing the highest degree of flexibility.

Application Description

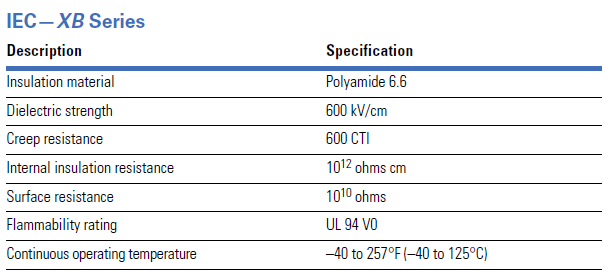

The metal portion of the XB Series terminal blocks are made from high-grade, straincrack and corrosion-proof copper alloys. They won’t experience any electrolytic corrosion or rusting, even when moisture is present. The metal surfaces are protected with a lead-free, galvanic nickel or tin plating. The good electrical conductivity permits only a low temperature rise. The Polyamide 6.6 housings allow for operating temperatures up to 257°F (125°C) and are certified for inflammability Class V0 in accordance with UL 94.

Features

Global acceptance—The XB

Series terminal blocks are designed to worldwide standards and meet the latest international requirements.

Flexible Plug-in bridge system—All three technologies (screw, spring and IDC) use the same bridge system, allowing for individual potential distribution and quickly bridged connections among the same terminal block type or across different types. The XB Series terminal blocks have two bridge shafts arranged in one line, making flexible chain bridging and skip bridging between nonadjacent terminal blocks possible. Plug-in bridges are available from 2 to 50 positions. Reducing bridges are also available to connect a larger terminal block to a smaller one.

Large surface area for marking—All XB Series terminal blocks have generously sized surface areas for labeling. This allows for clearly labeled wiring that results in reduced startup time and simplifies activities such as testing and maintenance. There are provisions for marking individual terminal blocks and end stops, strips of terminal blocks, and large groups of terminal blocks.

Standardized testing system—All test plugs make contact in one of the easily accessible bridge shafts. A 2.3 mm diameter test plug is available for individual measuring wires. Modular test plugs are also available for more advanced testing.

Standards and Certifications

- UL® and cUL® recognized—File No. E67464

- CE approved

- LVD 1

- EN 60947-7-1

- EN 60947-7-2

- EN 60998-2-3

- EN 60352-4/A1

- ATEX approval (Eex e applications)

Modular Terminal Blocks for Potentially Explosive Environments

The standard modular terminal blocks from Eaton are approved for potentially explosive environments. In addition to the usual approvals, they also have been approved by a testing center authorized by the EU. No extra approval is required in Intrinsic Safety type applications.

Modular terminal blocks on www.eaton.com fulfill the requirements for “Increased Safety” protection type when installation instructions are followed, and have a type examination certificate in accordance with the Ex directive Ex-RL 94/9/EU.

These test certificates are recognized in all the EU member states and beyond. The modular terminal blocks are approved for fitting in Zone 1, the Ex environment, as well as Zone 2. Zone 1 fitting is conditional upon terminal blocks being used in connection boxes approved for EEx e type protection and having the equivalent of at least IP54 protection.

The EEx approved modular terminal blocks can be divided into the following groups:

- Screw connection terminal blocks

- Spring-cage connection terminal blocks

- Insulation Displacement Connection terminal blocks

- Mini terminal blocks

Terminal blocks for specialized applications More detailed information on modular terminal blocks in the EEx e area is available on the Internet at www.eaton.com for downloading.

Here you will find the following:

- Technical data in accordance with EN 50 019

- Approved accessories

- Important installation instructions and mounting diagrams

- EU type examination certificates

- General information on Ex protection

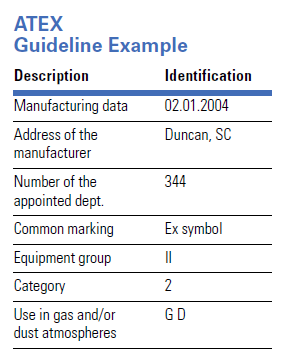

Identifications

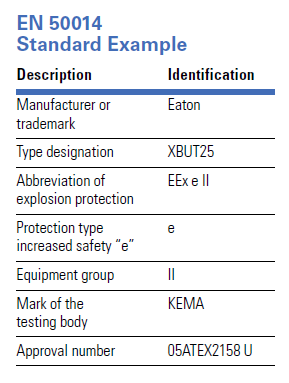

Explosion protected electrical equipment must be marked so that the safety characteristics are identifiable. The identification of electrical equipment is described in the harmonized standard EN 50014, as shown in the following example:

Identification in Accordance with ATEX-RL

Electrical equipment that is certified in accordance with the ATEX 100a guideline also receives identification describing the site for use.