AC30 Series General Purpose AC Variable Frequency Drives

AC30 Series AC Drive - Engineered for Flexibility, Simplicity, and Reliability

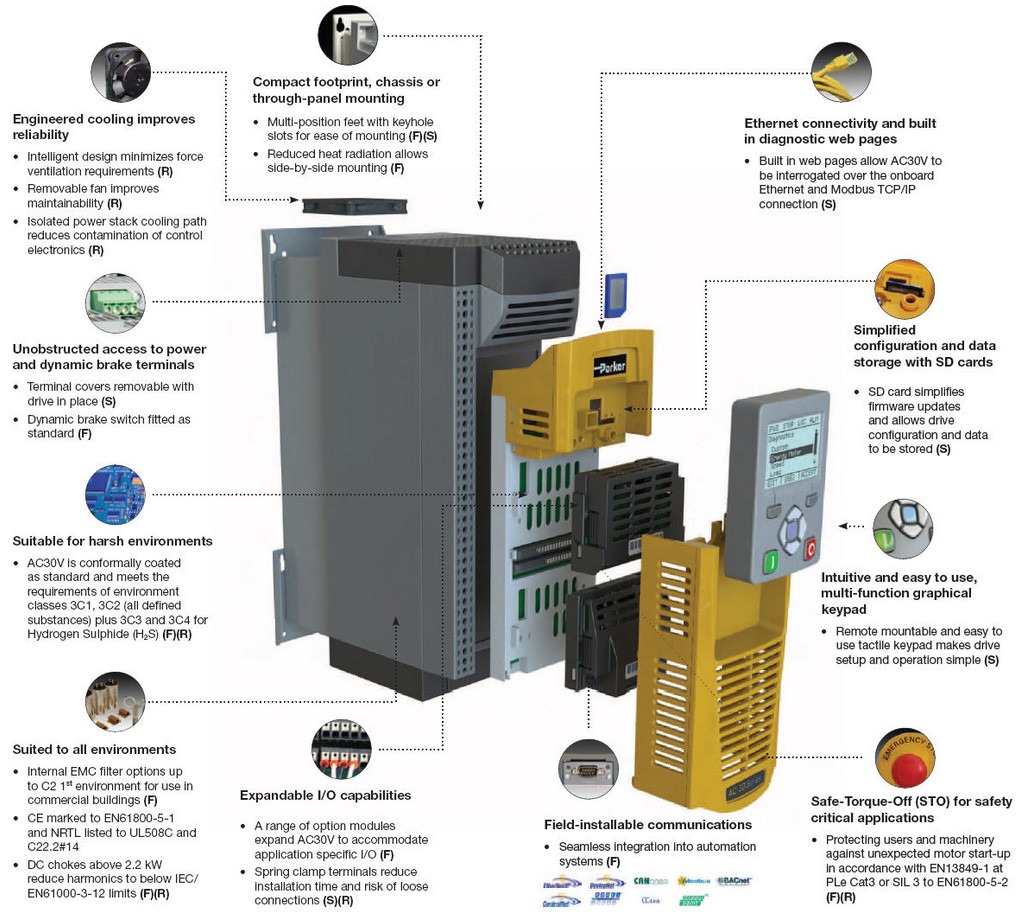

Key Features

- 1 to 600 Hp, 380 to 480 VAC 3-phase

- Modular Construction

- For Open and Closed Loop Applications

- Safe-Torque-Off (SIL3 STO) for safety-critical applications

- 3 Tech Levels - Basic AC30V, System AC30P, Advanced AC30D with dual encoder inputs and encoder output allowing “electronic line shaft” capability, phase locking between drives, and registration control, LINKnet time synchronized peer to peer comms built-in.

Flexibility

- Suitable for operation with AC induction and Permanent Magnet AC (PMAC) servo motors

- Ethernet TCP/IP as standard

- I/O expansion options

- Support for popular industrial fieldbuses

- Chassis or through-panel mount as standard

Simplicity

- Parker Drive Developer (PDD) software (Codesys IEC61131) or DSE Lite

- Multi-language graphical keypad

- Quick start wizards

- Terminal covers removable with drive in-place

Reliability

- Conformally coated for harsh environment protection as standard

- Spring clamp control terminal connections

- Isolated power stack cooling with removable fan

AC30 is supplied complete with many features designed to simplify pump and fan control. In addition to quick setup, dedicated pump and fan macros, there are a number of other features dedicated to energy-saving pump and fan control such as:

Automatic belt breakage detection

Interactive monitoring of the running conditions of a fan allows AC30 to detect breakage in the drive belt between the fan and motor, stop the motor and indicate an alarm condition.

Catching a spinning load - "fly-catching"

The fan control algorithms enable the AC30 to detect when a fan is free-wheeling and to regain control of it before running it at the commanded speed.

PID Control

Multiple PID control loops can be programmed to monitor process variables and adjust the speed of the motor accordingly to achieve the required variable setpoint.

Intelligent Pump Profiles

Our advanced intelligent pump control algorithms monitor motor loads and provide users with a number of features designed specifically for pump control applications, such as:

- Pump dry running protection

- Flow detection (low and no-flow)

- Blocked pump detection

Essential services (Fire mode)

Selected via digital input, Fire mode will cause the drive to run continuously at the maximum programmed speed ignoring all other control signals and alarm conditions.

Energy Optimization

Under constant speed conditions, the motor power waveforms from the drive are optimized to reduce motor energy consumption without compromising performance.

Skip Frequencies

Up to 4 speed and frequency bands can be programmed in the AC30, to enable resonant points on the fan to be avoided, reducing vibration, wear and noise.

Timed Run Function

10 daily start/stop events can be programmed with different running speeds across a 7 day period. This function requires the optional Real-Time Clock (RTC) module and is ideally suited to applications where regular operating patterns or periods of activity need to be accommodated such as in a production environment.

Process Timers

Multiple hours-run timers can be programmed to generate text alerts on the drive keypad to coincide with process maintenance intervals.

AC30 Catalog 11_2020

AC30 Catalog 11_2020

Software Reference Manual

Software Reference Manual

Manual Frame D-J

Manual Frame D-J

Phase Locking

Phase Locking

Manual Frame K-N

Manual Frame K-N

AC30 LinkNet Manual

AC30 LinkNet Manual

AC30_STEP_MODELS

AC30_STEP_MODELS

FAQ Site:

- AC30 Firmware revisions and numbering scheme

- AC30 Variations

- Available I/O

- How can the AC30 be programmed, and how to change the firmware between Codesys & LINKnet?

- How does the control word and status word in the AC30 work?

- HOW DOES THE INVERSE TIME (OVERLOAD) FUNCTIONALITY PROTECT THE DRIVE (AC30)?

- How to setup communications on an AC30V with CoDeSys firmware, to a TS8000 with Modbus?

- How to use the Scope Feature for the AC30 in PAM 1.4

- Running PMAC motors with the AC30 Drive

- There is an Extra Library that is added when adding a AC30 Device to a PAM 1.4 project?

- Updating PDD, using PAM 1.4 to setup an AC30 project, and connecting to an AC30 within PDD.

- Updating PDQ to the latest version

- What does the "STK" number mean on my AC30's heatsink?

- Where to find default configurations on the AC30?

- Why can't PDQ find my AC30?

- Why won't my AC30 clone from an SD card?

AC & DC Drives Full Line Selector Guide

AC & DC Drives Full Line Selector Guide