Parker Electromechanical

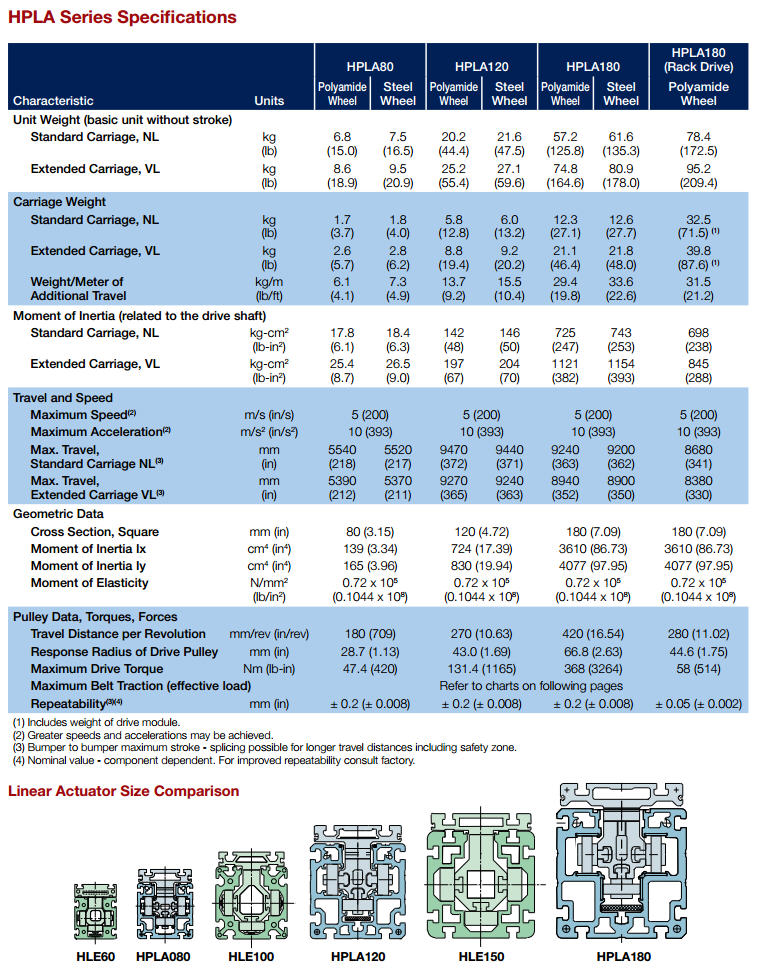

HPLA Series Belt Driven Linear Modules

HPLA Series Belt Driven Linear Modules

Key Features

- Designed to rapidly shuttle payloads to multiple locations

- Strong – steel roller bearing option for highest load capacity-1530 kg

- Rugged construction for heavy duty applications

- Thrust force capacity to 5455 N

- Standard travel up to 9 meters

- Velocity up to 5 meters/sec.

- Positional repeatability of ±0.2 mm

- Timing belt and pulley drive mechanism for fast, accurate positioning

Cad Configurators, 80, 120 and 180:

Modular drive system:

- Increased system stiffness due to larger belt width

- Low maintenance

- High performance due to hollow shaft input

Modular guide system:

- Provides an alternative to composite wheel material

- Quiet operation

- Low maintenance

- Steel wheel option on an integrated steel rolling surface for increased load capacity

- High load-bearing capacity

- High levels of rigidity

Various options for adaptation to wide ranging applications:

- Steel cover strip

- Corrosion-resistant stainless steel version for application in clean rooms or in the food industry

- Integrated position feedback system for maximum precision

- Optional IP30 rated strip sea

Proven Technology

- Direct mounting for planetary gear reducers – eliminating complexity of additional machined parts or couplings

- Adjustable “end of travel” limit switches and “Home” position sensor

- Cable carrier systems

- Performance matched Parker servo systems

- Structural components for vertical and multi-axis mounting

- Toe clamps and hardware for fast/easy mounting

- External bumper option

- Link shafts and support bearing for dual unit axes

- Splice plates for extending travels beyond length available in a single profile

HPLA Manual

HPLA Manual